|

|

Although the constant depth regulator mechanism on the drill press was not yet finished, I could not wait to make a few test runs. Finally I wanted to also know whether the Bungard drill bits were worth what I paid for them...

In order not to load the tools unnecessarily, I first used laminated paper circuit boards, which I picked up for a bargain price in the local electrical trade shop. I made the Atmel "in-system programmer" circuit board first as a test run. Unfortunately only the schematic was available at the Atmel server so I quickly made a suitable layout. For the first attempt the result was acceptable, although the position of the drilled holes was not in line with the milled circuit tracks.

|

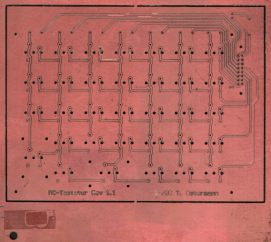

I was spurred on by the success to make a larger circuit board for a keyboard matrix for a micro CONTROLLER project. The card was already almost double euro format. The quality of the circuit board was such that it was bent from end to end when I bought it. In order to obtain an useful result I held down the circuit board on the machine table. Nevertheless fluctuations in depth of milling occured, so that I had to rework some parts of the board by hand. This time the drilled holes and milled circuit tracks were aligned.

Next I made my own version of the Insystem programmer for the 8051-Derivate. With the experiences I had gained to date, everything went a little quicker but fluctuations in depth of milling were still present. Two mills bits broke during milling. Obviously these milling bits (spear-head by Proxxon) are not suitable for this application. :-(

|